To say that the last few years of disruptions and economic uncertainties have been challenging for procurement leaders would be an understatement. Even now, rising prices, supply chain constraints, and rapidly changing consumer behavior are knocking companies off balance, making it clear that procurement leaders need to adopt strong data analytics capabilities to remain competitive.

There is hope. McKinsey research shows that businesses that leverage procurement analytics can boost their value delivery by 10-40%. But what exactly is procurement analytics, and how can you use this technology to join the ranks of successful businesses? Keep reading to find out.

Table of contents:

Procurement analytics involves collecting, analyzing, and interpreting procurement data to study how goods are ordered, sourced, and supplied. The process draws data from various sources, such as your inventory management and procurement systems, to help you make informed decisions.

Once the data is processed and stored in a centralized storage system, you may utilize a data analytics tool to visualize the data and find relevant patterns, trends, and anomalies.

1. Improving sourcing

Advanced procurement analytics tools incorporate predictive and diagnostic analytics capabilities, allowing you to uncover the ‘why’ behind events and forecast future trends. You can create demand forecasts, analyze sales trends, monitor supplier performance, and gain visibility into order cycles to better understand demand conditions, reduce storage costs, and adjust sourcing strategies for better operational efficiency.

Here’s how one of Harri’s valuable customers, The Radisson Hotel Group, uses ThoughtSpot’s custom Liveboards to achieve operational excellence:

“I can give a customized dashboard to our senior leadership team that provides a high-level overview of what’s going on. When we look at the detailed data, we can get to the root of any problem in any area, especially when the candidate pipeline is scarce; this enables us to anticipate upcoming issues and gives us the ability to plan, budget, and look at sourcing trends.”

2. Analyzing supplier performance

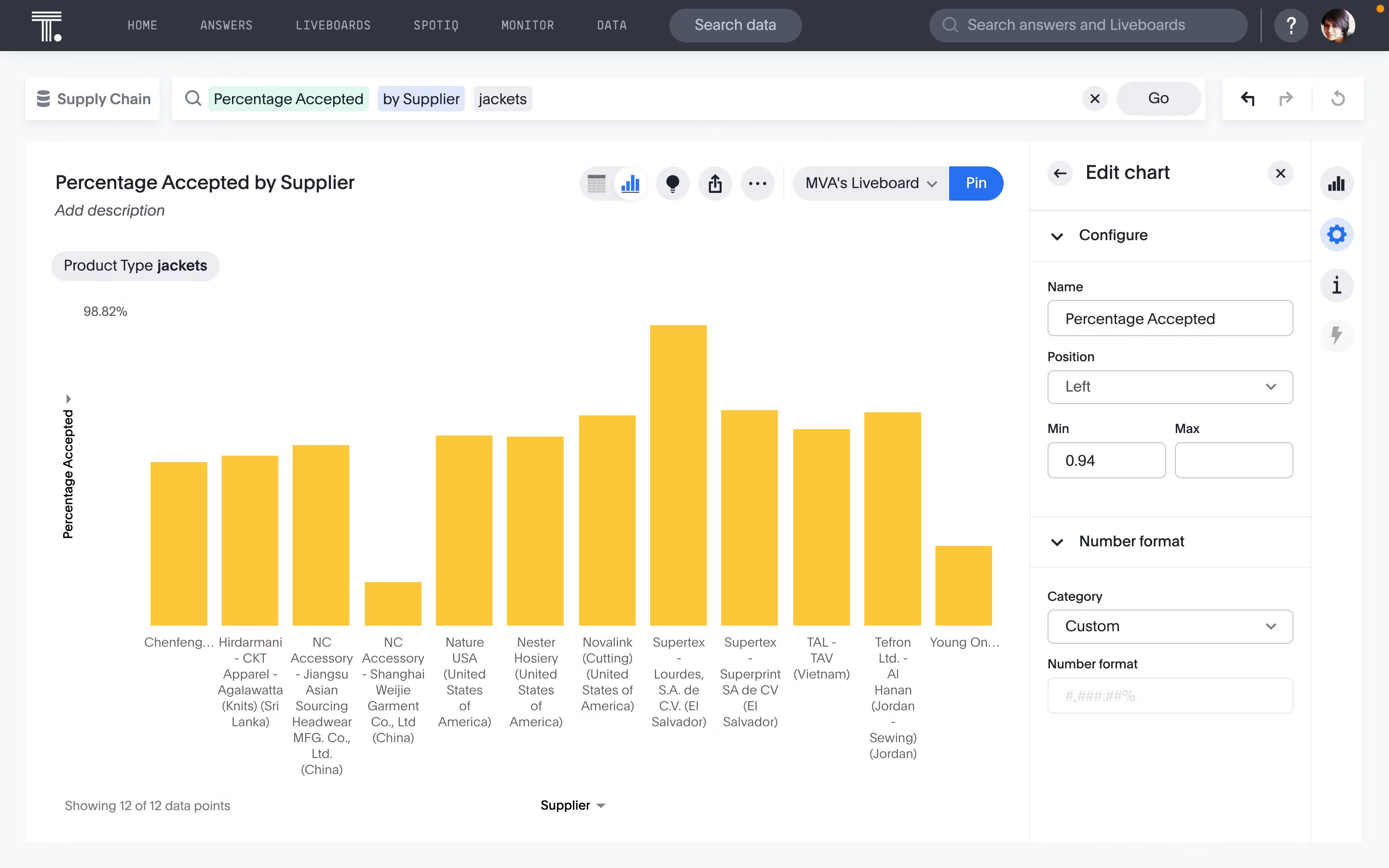

Managing a global supplier pool across multiple regions can be incredibly complex. From identifying the best suppliers to keeping track of lead times, you have to understand every supplier's operations and cost structures. Doing so will help you identify areas for cost reduction and minimize disruptions caused by delays in the supply chain.

With procurement analytics, you can monitor supplier performance through real-time supply chain KPIs, such as on-time delivery, quality of goods, pricing, customer care, and supplier lead times. This will allow you to establish clear quality expectations and benchmarks, leading to more favorable pricing terms and faster order fulfillment.

3. Enhancing bottom line

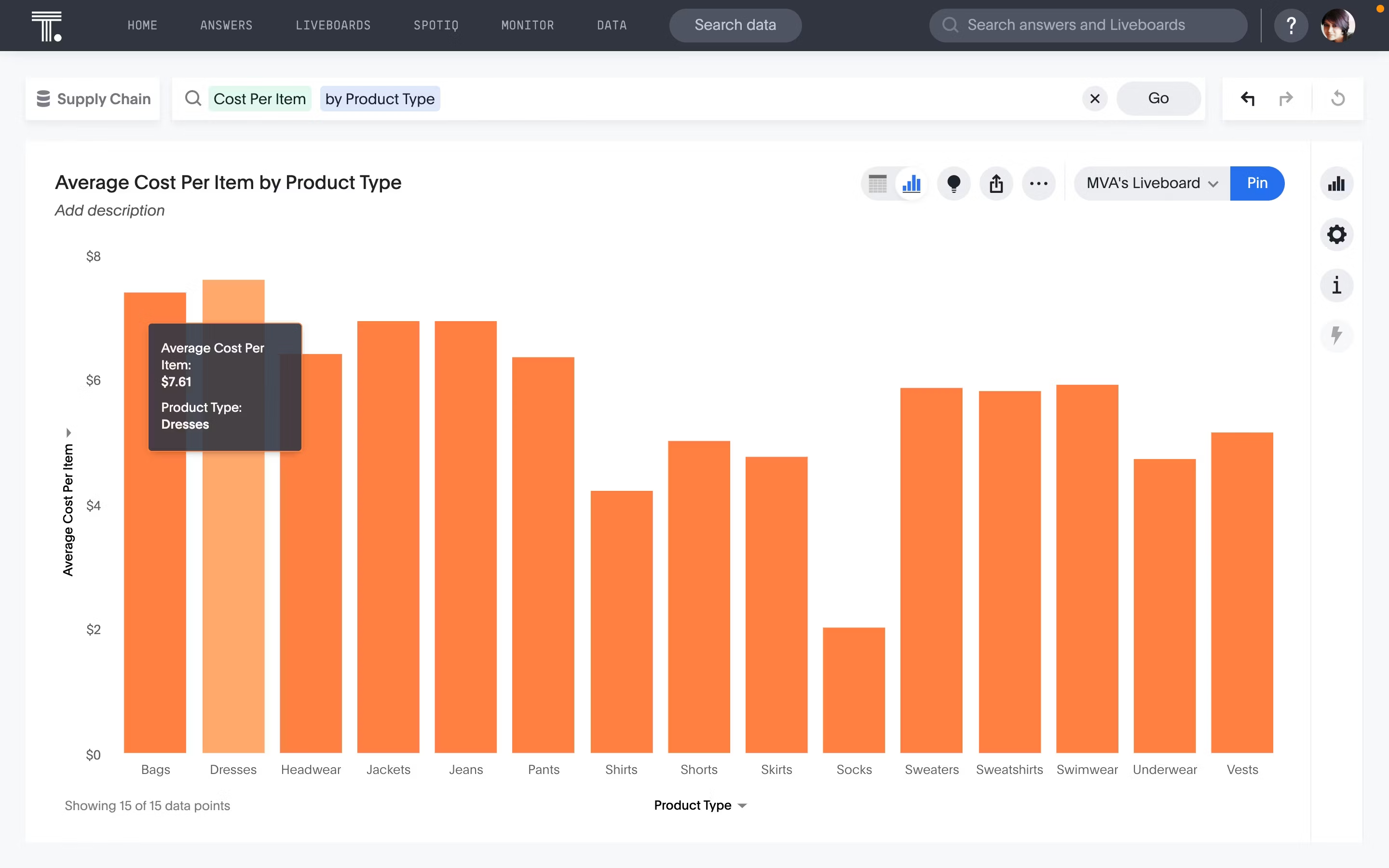

With procurement analytics, you gain end-to-end visibility into your entire value chain. By keeping a pulse on important procurement KPIs—such as purchase order cycle time, cost per item, and maverick spending—you can identify cost savings opportunities, optimize logistics, and streamline the procure-to-pay processes.

1. Descriptive analytics

Descriptive analytics is a type of data analytics that examines past data to help you answer the question ‘What has happened?’ in your business.

In the context of procurement, you can use descriptive analytics to understand the historical state of your sourcing data, everything from your purchasing order cycle to supplier defect rate. By piecing together all this information, you can gain a holistic understanding of your procurement process, allowing you to pinpoint operational inefficiencies and create proactive strategies to improve product scoping.

2. Diagnostic analytics

Diagnostic analytics utilizes advanced statistical techniques, such as data mining and root cause analysis to understand the ‘why’ behind events.

Consider the example below. By tracking KPIs, conducting supplier audits, and applying diagnostic analytics, you can identify the reasons for supplier performance issues. This analysis will enable you to provide necessary training and collaborate closely to address quality issues.

3. Predictive analytics

Predictive analytics uses advanced data analytics techniques, such as machine learning, AI, and statistical analysis, to forecast business outcomes.

Suppose that in the Fall, you had low inventory to meet consumer demand. With diagnostic analytics, you understood that this was because of slow deliveries. Now, with predictive analytics, you will be able to anticipate inventory levels for next Fall and take action to adjust procurement strategies accordingly. These actions may include diversifying your supplier pool or placing orders in advance to avoid stockouts during peak season.

4. Prescriptive analytics

Prescriptive analytics analyzes past and present data to offer insights into ‘what should you do?’ to achieve a business goal. Rather than showing you the data, prescriptive analytics goes one step further and suggests different action plans to guide procurement leaders in making informed decisions and streamlining workflows.

For instance, you can leverage prescriptive analytics to choose the best supplier profile for your business. This technique analyzes historical supplier data, current market trends, and qualitative and quantitative feedback to recommend supplier profiles that align with your organizational needs.

Procurement analytics is relevant to all types of businesses, as it quickly analyzes billions of rows of data from a variety of sources and gives you valuable insights into operations around procuring a product or service. Here we’ll explore some common examples of how leaders leverage procurement analytics to hedge raw material costs, manage supplier relationships, and plan their inventory:

1. Identifying bottlenecks in the purchase order cycle

Organizations that pay attention to their purchase order cycles naturally have lower lead cycles and higher profitability. With procurement analytics, you can inspect various aspects of your purchase order cycle, including the price at which goods are sourced, the contract terms, the cycle time by category, and the total closure time. This end-to-end visibility into the entire purchasing pipeline will help you pinpoint areas that need further improvements.

2. Managing procurement contracts

Tracking all contract agreements and expirations across global operations is a painstaking task many companies face. This can be especially complex when attempting to monitor multiple agreements with the same vendor across different categories and geographies.

Modern data analytics tools like ThoughtSpot can simplify this complex task. You can visualize your contract clauses and expirations by multiple dimensions, such as product type, country, and supplier location. You can even set up automated alerts that notify you whenever your contract expiration dates are near, helping you take swift action.

3. Decreasing rogue costs

You can decrease unnecessary procurement costs by understanding fluctuations in your budget variance and spending patterns. This detailed analysis will help you monitor how closely the actual procurement spending aligns with the budgeted amounts and indicates areas where your procurement activities are over budget.

In the example below, you can drill into specific categories to analyze your total spending more granularly and pinpoint areas where you can decrease costs and boost operational efficiency. Using ThoughtSpot AI-Powered Analytics, you can even auto-analyze your spend, uncovering a text-based analysis of factors driving the changes you see reflected in your visualizations—see it in action here:

No two businesses are alike. The KPIs and metrics you choose to monitor will vary depending on your specific business. However, here are a few of the most common procurement KPIs to help get you started:

1.Supplier diversity: Monitors the diversity of the supplier base in terms of demographics, size, ownership, and geographic location

2. Inventory turnover: Assesses how quickly inventory is being used or sold within a specific period

3. Maverick spend: Tracks the total expenses resulting from off-contract purchases

4. Defect rates: Measures the frequency of defects in the products or services supplied by the vendor

5. Contract compliance: Assesses the extent to which contracts are adhered to by suppliers, including pricing, delivery schedules, quality standards, and other terms and conditions

6. Total spend: Measures the overall amount spent on procurement activities within a specific period

7. Order to delivery cycle time: Gives the time taken from the placement of purchase orders to the receipt of goods or services

As we enter an age dominated by GenAI and analytics, having access to crucial insights is no longer a nice to have. With ThoughtSpot AI-powered procurement analytics, your team can combine procurement data from various sources, create a single source of truth, ask questions in natural language, and instantly get interactive visualizations with AI-augmented analysis.

Explore how easy it is to build Liveboards, drill into data, and find hidden insights. Schedule a ThoughtSpot demo today.